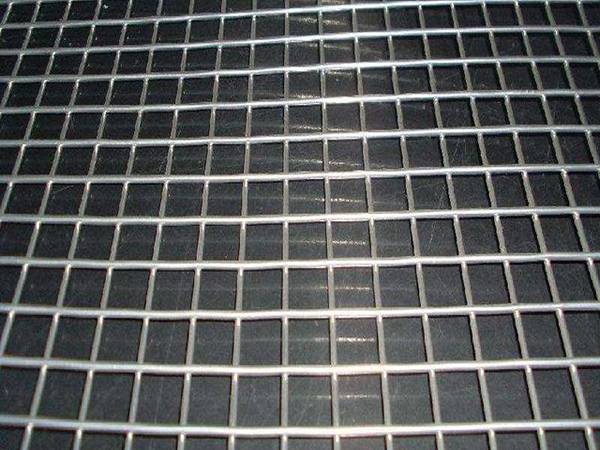

Welded wire mesh with dense mesh opening is good to prevent wall cracks.

As the development of the building energy efficiency and the new wall materials, the wall engineering faces kinds of problems such as, cracking and wall peeling. It has been found that the problems are due to the design, materials, construction, the base wall, the wall surface and the plaster layer. After the studying, the wall anti-cracking skill is summarized as design anti-cracking, material anti-cracking and construction anti-cracking. We have formulated some measures to solve the problems. For the material anti-cracking, we are going to use metal steel mesh, fiberglass mesh grid, chopped high performance organic fibers, elastic compound and so on.

Welded wire mesh with dense mesh opening is good to prevent wall cracks.

Galvanized expanded plastering mesh.

The steel mesh choice

The species of the steel mesh

There are kinds of steel meshes on the market, industrial screen mesh, fence mesh, safety structure mesh, agricultural mesh and screen window mesh. The different applications need different materials. But there is not professional steel mesh for the architecture anti-cracking. Thus there are many kinds of steel mesh for the engineering architecture wall. The following is the different steel mesh species.

The specifications for architecture wall steel mesh

| Steel mesh types | Material standard | Wire species | Shapes | Specifications (mm) | Using ranges |

|---|---|---|---|---|---|

| Welded wire mesh | carbon steel GB/T 700 | electro galvanized low carbon steel wire | Rolled | wire diameter: 0.4–0.9 mesh opening: 9.5–19 |

interior wall |

| rolled | Wire diameter: 2.2–4.0 mesh opening: 25–50 |

exterior wall | |||

| electro galvanized low carbon redrawn wire | rolled | wire diameter: 0.4–0.9 mesh opening: 9.5–19 |

interior wall | ||

| rolled | wire diameter: 2.2–4.0 mesh opening: 25–50 |

exterior wall | |||

| Butt welded wire mesh | carbon steel GB/T 700 | electro galvanized low carbon steel wire | panels | wire diameter: 2.2–4.0 mesh opening: 25–200 |

exterior wall |

| cold-drawn low carbon steel wire | panels | wire diameter: 2.2–4.0 mesh opening: 25–300 |

exterior wall | ||

| Expanded metal | cold rolled expanded metal GB/T 708 | diamond shape mesh opening, rectangle strand | rolled | sheet thickness: 0.4–1.0 strand thickness: 0.4–1.0 mesh opening: 12 × 25–8 × 16 |

interior wall & exterior wall |

| Galvanized welded wire mesh | carbon steel GB/T 700 | hot-dip galvanized steel wire | rolled | Wire diameter: 0.9–2.2 mesh opening: 12.7 × 12.7–50.8 × 50.8 |

exterior wall thermal insulation |

The choice principle

The principles for choosing the architecture wall steel mesh is summarized based on the use effect.

The choice for the exterior wall

The metal mesh choice for the interior wall

The anti-cracking is needed for the parts between the column and the beam, and the parts on the door hole and the buried pipeline, we need welded wire mesh. The diameter of the wire is 1 mm–1.2 mm, and the mesh opening is 15 mm–20 mm. The galvanized expanded metal is also needed. The thickness both of the panel and the strand is 0.6 mm. The mesh opening is 10 mm × 20 mm. The weight is 0.56 kg/m2.

The construction technology of installing wire mesh

The normal installing wire mesh technology

We should clean the surface of the masonry and do the base of the surface and choose the steel wire mesh. We should do the prepares for nailing, welded steel wire mesh, mortar plastering, the anti-cracking mortar wire mesh and do the systemic inspection.

The prepares before attaching the wire mesh

The technology of plaster mesh

Plastering after installing the wire mesh

The discussion of plaster mesh

The steel mesh for frame fill wall

We have studied about the frame fill wall. The cracks between the masonry and the frame are unavoidable due to the different materials and construction time of frame fill wall structure. Thus the decorative layer would crack and wall would peel sometimes. To prevent the wall cracking and peeling, attaching the steel wire mesh is the first choice among the measures.

The safety of the steel mesh

The effect for the exterior wall steel mesh is to prevent the plastering layer and decorating layer from cracking and accident. We know the certain position and the steel content during concrete casting so the plaster is firm. But the plaster mesh is wrapped with the lime and its wire is thin the firmness with the foundation is not so good. The plastering layer and the masonry foundation have poor performance, the wall foundation and the plastering layer force different stress so it's difficult to make sure the steel wire mesh can last for long time. At present, the steel wire mesh as anti-cracking wall and anti-peeling is used only for safety warning. To a certain extent the steel mesh could prevent the wall from the cracking and cavity for a long time. So it would reduce the probability of the safety accident and the peeling of the wall. We should make a new design for the exterior wall structure safety.

The effect of the steel mesh for the cracking

According to the survey the cracking could cause the leakage, so attaching the steel mesh for the connecting part is necessary. It could reduce the cracking, cavity and leakage. The performance of the steel mesh could not exert well because some high building walls are not so strong and the adhesion is not good. But according to the requires, different steel wire meshes are used for corresponding parts. The cracking can be reduced a lot. The leakage can even be controlled totally. With the development of the anti-cracking technology, the steel mesh is the best choice for anti-cracking. The using effect of the steel wall is related to its material, standard, plaster style and construction.